Our Approach to Quality Assurance

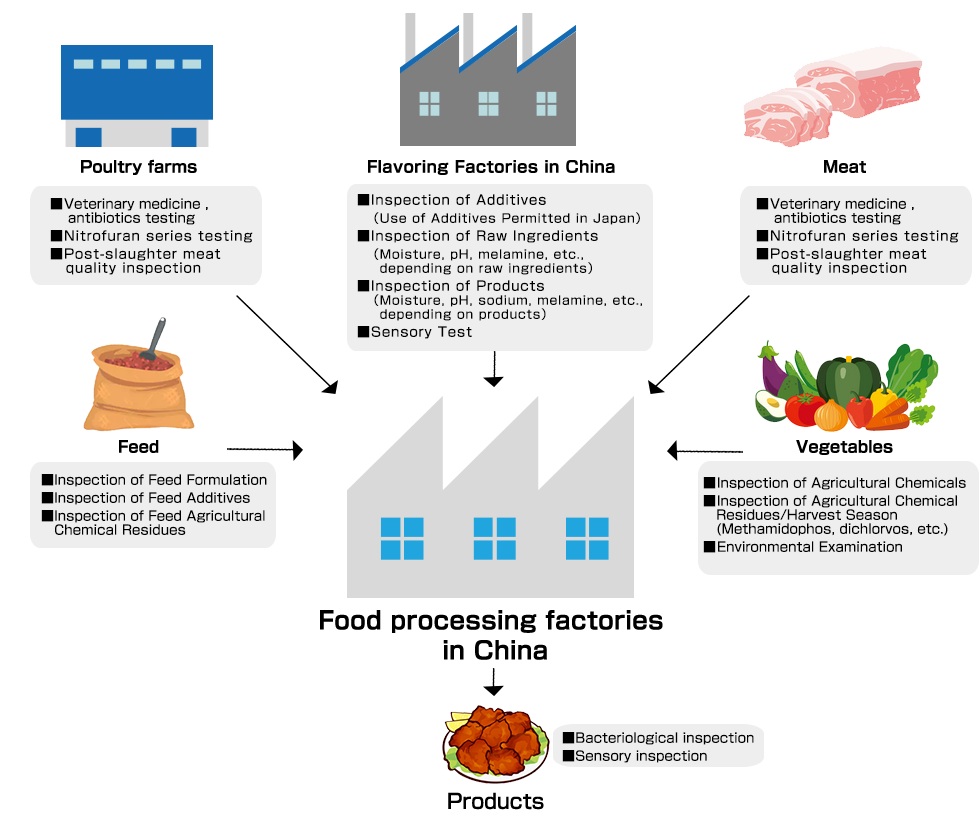

We import and sell only products which have passed many kinds of food inspections at local factories and observe Food Sanitation Law in Japan to provide secure and safe products for our customers. The factories in China have an integrated production system from poultry farming to manufacturing, production, logistics, and sales.

In addition, they have certification of Ministry of Agriculture, Forestry and Fisheries of Japan, HACCP, and ISO.

Seasoning Factory

Flow Chart for Raw Ingredients

Receiving Raw Ingredients

We conduct the following inspections by receiving lot units on receipt of raw ingredients.

| Wheat Flour | Preservatives, sweeteners, Sudan dyes, aflatoxin, pesticide residue |

|---|---|

| Fruit Juice/Vegetables | Preservatives, sweeteners, Sudan dyes, aflatoxin, pesticide residue |

| Animal Protein | Preservatives, sweeteners, Sudan dyes, antibiotics, melamine |

| Food Colors | Preservatives, sweeteners, Sudan dyes, aflatoxin, pesticide residue |

| Fats and Oils | Antioxidants, pesticide residue |

| Liquid Seasonings (soy sauce, starch syrup, sake, mirin, etc.) |

Preservatives, sweeteners, pesticide residue, melamine |

| Seasoning Poweders (starch, spices, etc.) |

※The frequency of inspections depends on raw materials. ※We conduct inspections 100% for the first receipt. (Random inspections regulary from next ones) |

Products

We conduct the following inspections by production lot units for the final products.

・Bacteria tests (viable bacteria, coliform bacteria)

・Sensory tests (taste, smell, colors, etc.)

| Liquid Seasonings | Preservatives, sweeteners, antioxidants, Sudan dyes, aflatoxin, pesticide residue, antibiotics, melamine |

|---|---|

| Seasoning Poweders (starch, spices, etc.) |

Preservatives, sweeteners, antioxidants, Sudan dyes, aflatoxin |

Shipment

| Water Quality Test | We outsource quality test of water used on production twice a year. In addition, we conduct inspections of viable bacteria, coliform bacteria, residual chlorine, and pH level once a week on our own. |

|---|---|

| Sampling Inspection | We conduct inspections of viable bacteria and coliform bacteria for facilities, equipment, workers’ hands, work tables, and so on at factories once a week. |

Food Processing Factory

Processed Chicken Foods

Poultry Farming

How Poultry Farms Look

Broilers bred at factories in China are raised with high-quality feed.

In addition, we use only animal drugs and antibiotics with permission.

Production

How Production Is

The factories in China perform hygiene management conformable to HACCP.

Moreover, production records on all process enable traceability.

Inspection

How Inspection Is

We check our final products according to the following inspection items and ship out only ones which have passed them.

If needed, when it’s impossible to conduct inspections on our own, we outsource them.

| Inspection of Products |

・Microorganism test (viable bacteria, coliform bacteria, E. coli, Salmonella spp., Staphylococcus aureus) ・Sensory test (taste, smell, texture, shape, color, etc.) ・Antibiotics residue test |

|---|

Processed Marine Foods

Receiving Raw Ingredients

The local factories prohibited to use chemicals. We purchase secure and safe shrimps from farms which we have contract with. Shrimps freshly caught in the morning are transferred to factories

Production Management

The local factories perform hygiene management conformable to HACCP.

They conduct quality inspections and records for raw ingredients and final products.

(Microorganism test, bacteria test, sensory test)

Only final products which have passed all quality inspections are shipped out for Japan.